The throttle position sensor (TPS) is a vital component in a vehicle's fuel injection system. It is responsible for providing the engine control module (ECM) with information about the position of the throttle valve, which controls the amount of air entering the engine. Without a functioning TPS, the engine may not run properly or may not start at all. In this article, we'll explain the function and importance of the TPS and how to diagnose and troubleshoot issues related to it.

What is a Throttle Position Sensor?

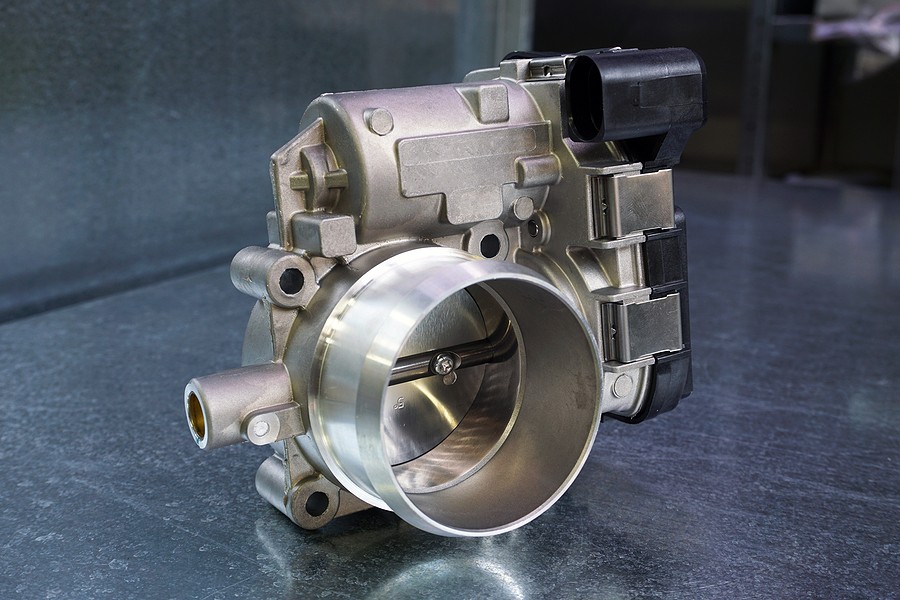

The TPS is a variable resistor that changes resistance based on the position of the throttle valve. The sensor is typically located on the throttle body and is connected to the throttle linkage or cable. As the throttle valve opens and closes, the TPS sends a varying voltage signal to the ECM. The ECM uses this signal to determine the throttle position and adjust the fuel injection and ignition timing accordingly.

How Does the Throttle Position Sensor Work?

The TPS works by sensing the position of the throttle valve and sending a corresponding electrical signal to the ECM. The ECM then uses this signal to adjust the fuel injection and ignition timing.

When the engine is at idle, the throttle valve is closed, and the TPS sends a low voltage signal to the ECM. As the driver presses the accelerator pedal, the throttle valve opens, and the TPS sends a higher voltage signal to the ECM. The ECM uses this signal to increase the fuel injection and advance the ignition timing, which results in a corresponding increase in engine power.

Symptoms of a Bad Throttle Position Sensor

A malfunctioning TPS can cause a variety of symptoms, including:

- Hard starting

- Stalling

- Hesitation or stumbling during acceleration

- Reduced power

- Reduced fuel efficiency

- Check engine light illumination

How to Diagnose a Bad Throttle Position Sensor

To diagnose a bad TPS, you'll need to check the sensor's voltage signal with a digital voltmeter. Here's the step-by-step process:

- Locate the TPS on the throttle body.

- Connect the negative lead of the voltmeter to a good ground on the engine.

- Connect the positive lead of the voltmeter to the TPS signal wire.

- Start the engine and let it idle.

- Check the voltmeter reading. It should be between 0.45 and 0.55 volts.

- Slowly open the throttle valve by pressing the accelerator pedal.

- Observe the voltmeter reading. It should increase smoothly as the throttle valve opens.

- If the voltmeter reading is abnormal or the signal is erratic, the TPS is likely faulty and should be replaced.

How to Replace a Throttle Position Sensor

If your diagnosis confirms a bad TPS, you'll need to replace it. Here's the step-by-step process for replacing the TPS:

- Locate the TPS on the throttle body.

- Disconnect the electrical connector from the TPS.

- Remove the TPS mounting screws or bolts.

- Carefully remove the TPS from the throttle body.

- Install the new TPS and tighten the mounting screws or bolts.

- Reconnect the electrical connector to the TPS.

- Start the engine and check for proper operation.

FAQs

What is the function of a throttle position sensor?

The throttle position sensor (TPS) is a sensor that measures the angle of the throttle valve, which controls the amount of air entering the engine. This information is used by the engine control module (ECM) to adjust the fuel injection and ignition timing for optimal engine performance.

2. What are the symptoms of a bad throttle position sensor?

A faulty TPS can cause a variety of symptoms, including poor engine performance, stalling, rough idling, and difficulty starting the engine. The “check engine” light may also turn on.

3. How often should the throttle position sensor be replaced?

It is generally recommended to replace the TPS as part of regular maintenance, typically every 80,000-100,000 miles. However, if the TPS is showing symptoms of failure, it should be replaced as soon as possible.

4. Can a dirty throttle body cause problems with the throttle position sensor?

Yes, a dirty throttle body can cause problems with the TPS. Dirt and debris can build up on the throttle plate, which can cause the TPS to give incorrect readings. This can lead to poor engine performance and other issues.

5. Can a throttle position sensor be repaired?

In most cases, a TPS cannot be repaired and must be replaced if it is faulty.

6. Can a throttle position sensor cause a car to stall?

Yes, a faulty TPS can cause a car to stall, as it can send incorrect information to the engine control module, which can result in poor fuel injection and ignition timing.

7. Can you test a throttle position sensor?

Yes, a TPS can be tested using a diagnostic scan tool or a multimeter. A mechanic or technician can check the sensor's output voltage and compare it to the manufacturer's specifications to determine if the TPS is functioning properly.

8. Can a throttle position sensor cause poor fuel economy?

Yes, a faulty TPS can cause poor fuel economy as it can send incorrect information to the engine control module, which can result in poor fuel injection and ignition timing.

9. What is the average cost to replace a throttle position sensor?

The cost to replace a TPS can vary depending on the make and model of the vehicle, as well as the location of the repair shop. On average, the cost can range from $50 to $300.

10. What is the difference between a throttle position sensor and a throttle control motor?

A throttle position sensor (TPS) measures the angle of the throttle valve, while a throttle control motor (TCM) is an electric motor that controls the position of the throttle valve. The TPS sends information to the engine control module, which then uses that information to adjust the fuel injection and ignition timing, while the TCM physically moves the throttle valve to open or close.

Conclusion

In conclusion, the throttle position sensor (TPS) plays a crucial role in a vehicle's fuel injection system by providing the engine control module (ECM) with information about the position of the throttle valve. Without a functioning TPS, the engine may not run properly or may not start at all. Symptoms of a bad TPS include hard starting, stalling, hesitation or stumbling during acceleration, reduced power, reduced fuel efficiency and check engine light illumination. To diagnose a bad TPS, one can use a digital voltmeter to check the sensor's voltage signal. If the diagnosis confirms a bad TPS, it should be replaced. The process for replacing the TPS involves locating it on the throttle body, disconnecting the electrical connector, removing the TPS mounting screws or bolts, installing the new TPS and reconnecting the electrical connector. It is important to be aware of the symptoms and how to diagnose and replace a bad TPS to ensure proper functioning of the vehicle's fuel injection system.